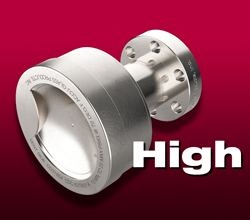

7.5 ~ 25 PSI Burst Discs

Vacuum Burst Disc

Vacuum systems are engineered to operate under external (atmospheric) pressure loads, and were never intended for internal pressurization. Accu-Glass pressure burst discs are important and preventative safety devices designed to protect vacuum systems against accidental over-pressurization. Failure of internal gas or cryogenic fluid supply lines can lead to rapid pressurization inside a vacuum vessel — well above its internal load limits. Besides protecting delicate system instruments and equipment — such as vacuum viewports — bursting discs (pressure burst disk) minimize the risks of injury to system operators and personnel.

How do Vacuum Rupture Discs Work?

Simple — pressure buildup inside a vacuum vessel deforms a concave thin metal-foil diaphragm, pushing it against radial tab built into a burst disc's housing. The diaphragm ultimately ruptures providing an instant pressure relief path for a vessel's internal volume. All pressure burst discs have a unique stress-pattern scored onto the metal diaphragm, effectively pre-stressing it for precise pressure and rupture control. Accu-Glass vacuum rupture discs have large deflection areas, and are available / certified for two pressure ranges. Low-pressure units rupture between 7.5 and 11.5 psi, while High-pressure units rupture between 15 and 25 psi. Note that a ruptured burst disc cannot be repaired! Once a unit fails, it must be replaced in order to make a vacuum system operational again.

Caution! Note that AG burst-disc pressure relief ratings are @22.2°C (72°F), so operating these devices at higher temperatures will reduce their burst pressure rating.

CLICK ON A BURST DISK CATEGORY BELOW TO SEE PRODUCTS AVAILABLE FOR PURCHASE